McQuillan Boiler Services

Boiler Insurance

Boiler insurance & NDT Inspection

McQuillan’s Boiler maintenance team of skilled engineers operate throughout the U.K carrying out Steam Boiler Preparations for statutory Annual Boiler Insurance inspections and NDT Testing. Our team of experienced Boiler engineers will spot any major problems before the arrival of the insurance inspector and look to repair it before the inspector arrives on site, this will save downtime and costly second visits of the Boiler inspector. Should your boiler need any additional work such as, chemical descaling, retubes or NDT repairs then our team of highly skilled engineers can assist you in this.

What makes McQuillan’s Different?

As part of a standard Boiler annual inspection our team of skilled Boiler engineers will bring all Boiler Valve’s back to our Valve maintenance Workshop. When the Valves reach our Workshop our Valve engineers will refurbish and certified the valves ready for our rebuild team to come back to site and re-build your boiler.

What is Included in a MBS Boiler Inspection?

- Detailed Risk assessment

- Boiler Valves re-moved from the Boiler

- Boiler Opened up for Inspection

- Tubes and tubeplate cleaned

- All flanges cleaned

- All nut and bolts copper greased

- Valves transported back to our in house valve maintenance workshop

- Valves repacked, pressure tested and certified

- Safety Valves Tested and set to the desired pressure

- Engineers can meet the boiler inspector on site

- All gaskets needed

- Gauges recalibrated

- Boiler rebuilt and steamed up to pressure

- Our engineers will conduct a full working test before signing the job off

What is included in a MBS Boiler NDT Inspection?

- Detailed risk assessment

- Remove all cladding and lagging on Boiler to expose welds

- Remove brickwork/refractory

- Prepare all welds in accordance with SAFed SBG 1 / 2

- Engineers can meet with your NDT Inspector

Once passed by Inspector

- Refit or replace any external cladding and lagging

- Our refractory team will refit new refractory

- hydraulic test if the Boiler has had an NDT repair

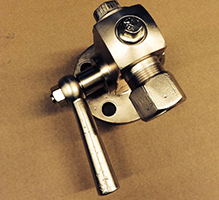

What goes on inside our Valve Maintenance workshop?

The valve is back at our workshop and is ready to be stripped. Gaskets are taken off and all valve details are recorded and logged.

Next the valve is stripped and all old packing is removed. The components are placed in a box and sent of for sand blasting and polishing.

Now the valve has returned from cleaning it can be checked for any pitting in the valve and the spindles are replaced if required. Now the valve is ready to be re-packed and assembled.

The valve is now re-built and can be tested using nitrogen. Once it has passed a test, a certificate can be made out, the valve is now ready to be fitted to the boiler.

Trusted By

Read Testimonials

Epoxy Curing Agents / Maintenance Team Leader

Pets Choice Ltd / Chief Engineer

JBC Global Supply Chain / CEO

Greencore Grocery Ltd / Site Services Manager

Interpac / Business Development

Seven Bro7hers Brewery / Director